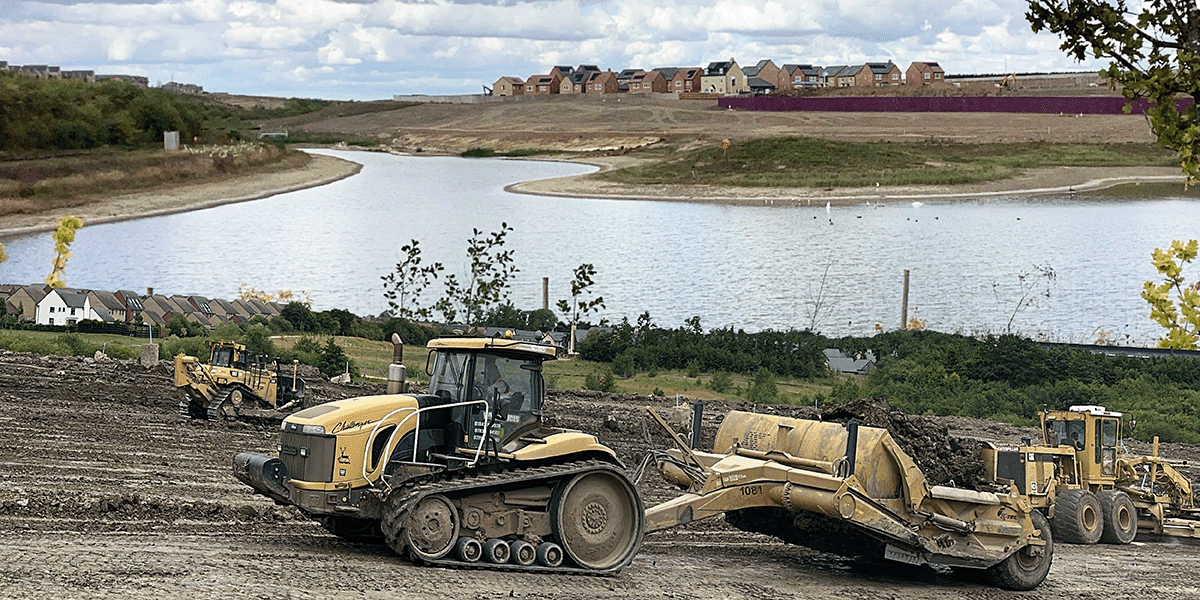

Once the heart of an ironstone quarry fueling the local steel industry, this site is now on the path to becoming a thriving neighbourhood, thanks to Urban&Civic’s visionary efforts. With outline planning consent secured for an impressive 5,350 new homes, residents will also enjoy access to primary schools, designated employment areas, and thoughtfully designed open spaces complete with play areas and sports pitches.

In April 2024, ECL proudly took the reins as principal contractor, embarking on a transformative journey with the earthworks project on this historic land. With work kicking off on 3rd June 2024 and wrapping up on 6th September 2024, our team dedicated 14 weeks to shaping the next strategic stage of parcel-engineered fill, including surcharge for our client in Priors Hall Park.

The surcharge of land required a proficient team to strategically install a grid of settlement monitoring rods and regulate the height and compaction of the surcharge material. Our approach not only facilitated the careful placement of materials but also created a robust framework for processing and interpreting reliable monitoring data.

Senior Planner Geoff White commented, “With real-time data at their disposal, our engineers could accurately measure pore water pressures and surface settlements. This enabled them to track the progress of consolidation and confidently estimate the necessary duration for treatment.”

Geoff continued, “The timelines and the level of detail required presented us with a significant challenge. We needed to carefully extract monitoring rods from an existing land parcel and strategically arrange them in a grid pattern while closely collaborating with Shadbolt. Moreover, we needed to emphasise ensuring the fill was correctly compacted, which proved to be a

meticulous task. The coordination involved really highlights the magnitude of the job.”

Billy Plant, our Contracts Manager,

shared his insights on the fast-paced nature of the project, “Corby was a high-energy program; the sheer volume of muck to shift in such a short time was daunting!” he recounted.

The weather, however, threw us a curveball right from the start. “We began on the back foot due to some pretty challenging conditions,” Billy explained. “But we quickly adapted, ramping up our resources mid-contract to stay on track.”

This adaptability was a testament to the site team’s precision in recording daily click counts for every task, with the data shared for weekly and, at times, daily reviews. Intermediate drone survey flights further enhanced their efforts, providing a dynamic visualisation of ongoing progress. Billy noted, “This approach allowed us to have all the crucial data at our fingertips, enabling us to monitor, manage, and adjust our resources in response to the constantly changing conditions around us.”

With the client’s geotechnical team from Shadbolt keeping a watchful eye, we knew precision and transparency were key. “Their rigorous scrutiny meant we had to bring our A-game,” Billy noted. “We couldn’t afford any slip-ups, and we were determined to keep everything moving smoothly.”

As the project progressed, we encountered delays, but instead of backing down, we leaned into the challenge. “We mobilised more equipment and maximised our daily working hours, adhering to the planning consent and our own workforce fatigue policy to ensure safety. Despite the challenges faced, we embraced each obstacle, determined to leap over every hurdle,” he shared, a glint of resolve in his eyes.

In an incredible show of teamwork, we orchestrated the placement of a staggering 300,000 cubic meters of surcharged material in just 14 weeks! The operation called for six Challenger and Motor scarper boxes, four rollers, and three powerful dozers to work simultaneously. “We were cutting and placing to engineered fill to over 30,000 cubic meters each week!”

Shadbolt Consulting Limited played a crucial role throughout this journey, providing a full-time watching brief that ensured every layer of the earthworks was monitored, tested and verified. “With four dedicated engineers on-site, our collaboration was seamless,” said Bill. “We tackled challenges together, united by our mission to keep the project on track.”

“As we completed each layer, the engineers meticulously verified the testing results before moving forward. Our team was fully prepared to revisit previous layers if any issues arose, but we aimed to prevent such situations at all costs,” Billy stressed.

Geoff added, “The team delivered exceptional results by ensuring that both long-term primary and secondary settlements were well within acceptable limits. Additionally, the ground’s enhanced strength and stiffness confidently met all design specifications without issues.”

This commitment to precision and effective communication laid a strong foundation for a rewarding relationship with Shadbolt Engineering, ensuring we delivered the project to the highest standards.

With immense pride, we celebrated the successful completion of the project on 6th September, receiving Shadbolt’s official seal of approval. Their endorsement—the coveted “tick of acceptance” on our compiled post-construction documentation requirements — was the ultimate affirmation of our hard work and dedication.

This moment signifies not just the completion of a transformative chapter in Corby but the birth of a thriving community filled with promise for years to come.