Digital Machine Control in Construction

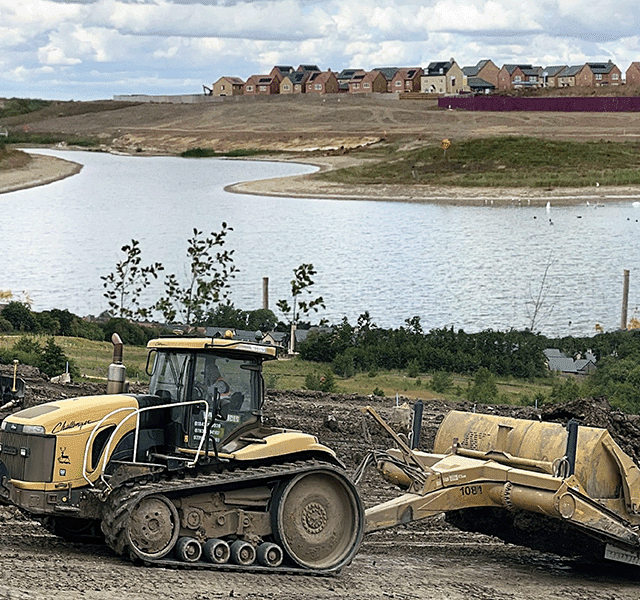

Through GPS machine guidance and automation, digital machine control in construction has already played a huge role in improving our site efficiency and safety. But what’s exciting, if adopted correctly, is the possibility of machine control resolving some of our most pressing issues, if not those of the entire industry.

Simply defined, machine control is a system integrated into construction equipment and machinery. Using electronic sensors, actuators, controllers, and software algorithms, it optimally automates machine excavation calculations and operation, making heavy construction work faster and safer. What’s more, the tech is only getting better. Some incorporate principles from control theory, machine learning, and artificial intelligence to adapt and adjust to changing environmental conditions and task requirements.

ATTRACTING NEW TALENT

With many experienced machine operators approaching retirement and the construction sector struggling to attract a new generation, the widening skill gap and labour shortage is one of the biggest challenges facing construction projects.

In a report by Topcon, 77% of construction professionals acknowledge that machine control is a leading component when it comes to attracting talent. With the ease of implementation and operation control alongside an average increased efficiency of 50%, machine control is believed to widen the pool of candidates for heavy equipment operations and ultimately lessen the labour force requirements on-site.

We caught up with Richard Appleby, who has 11 years with the company and is one of our most senior and accomplished machine operatives, for his take on machine control and its benefits.

“I currently operate the SK210 Kobelco with an SMP Tilt Rotator; it’s one of the latest machines. It’s like the Ferrari of machines, and there’s nothing out there on the market that could touch it.

Pre-built models are sent remotely to my machine, and I’m left in control along with the GPS screen to deliver the work. The GPS makes me more productive and efficient as I have all I need in front of me to produce the work to a tolerance of 10-20mm. It also makes my working environment safer because GPS means fewer men around the machine in my red zones.

It sounds simple, but with less need for supervision, it means you need to be entrusted and you need to understand your machine. I’ve had years and years of experience, and though these models are safer and easier to use, you still have a high level of responsibility to control the works, which is a skill you can’t fast-track.”

Site Manager Kieran Devane added,

“Richie is undoubtedly one of the best drivers in the UK, and I don’t mind saying that.

I’ve been working with him forever; he’s part of my team, and I’ve been lucky enough to have him in my projects for the last eight years.

Richie is right about trusting your team. Before the world of GPS, I had to monitor works managed by our machine operatives. Now we give them a lot of trust and rely on them to produce good products with this kit.

If I swapped any of our experienced GPS operators out and got an agency lad, even if I had six weeks to train them, there is no way they would be up to their level. I do have to credit our GPS operators within the business for their skillset and the loyalty they show.”

Machine control is perhaps not as simple as it sounds, yet there is hope that it will excite newcomers and encourage them to train for a sense of independence and responsibility.

SUSTAINABLE CONSTRUCTION

The built environment industry must, however, make significant improvements to its sustainability. In a recent publication, the UK Green Building Council (UKGBC) found that the industry was decidedly off-track from the trajectory required to meet the UK’s net zero commitments.

It is not an utter disaster, as a report published at COP26 in Glasgow revealed that carbon emissions from the UK built environment did fall by 13% between 2018 and 2022. Yet this 13% is shockingly low in comparison to the 19% required to meet the UK’s net zero pathway. The report places needed pressure on the construction sector to adapt and operate more sustainably.

Without a world, what is there to build on?

LESS MATERIAL WASTE

Machine control dramatically reduces material waste as operators can be far more accurate. Take Appleby’s SK210 Kobelco or “Ferrari of machines” as a key example, boasting a tolerance of 10-20mm. Operators like Appleby can accurately position earthwork machinery, allowing for precise digging and grading to get the results they want the first time, every time.

We spoke to Engineering Manager Francis Gillespie about ECL’s wider use of machine control:

“ We have a fleet of more than 50 GPS machines… 7 bulldozers, 2 tracked loading shoves, and about 40 excavators ranging from 13 to 35 tonnes.

In addition to our fleet, we use drone surveying equipment. We have just purchased a new drone, the DGI Mavic, which we use for 3D surveys to calculate volumes and survey infrastructure sites to an accuracy of 15mm.

We are already ahead of the curve in our extensive use of machine control, and, with the helpful assistance of drones, we are able to keep projects highly accurate, with as little waste as possible.”

INCREASED EFFICIENCY

Machine control has an immense impact on efficiency. It takes far less time to follow a screen than to decipher marks on the ground, so it is unsurprising that, when laying a foundation, GPS technology alone saves a minimum of 4 hours. On a 100-home development, that amounts to a whopping 16 days! Moreover, a second person is no longer required to check the dig level, which only further reduces man hours and increases efficiency. No profiling the ground, no remediation and no risk of incorrect finished levels and weeks can be saved.

REDUCED FUEL

The increased simplicity and quick accuracy of machine control also reduces the amount of time the engine is left running or idle. This lessens fuel consumption which both has obvious cost benefits and helps the planet by limiting carbon emissions. Machine control is itself an exciting means of combating troublesome carbon emissions. It reduces material waste, increases efficiency, and cuts fuel use.