Sustainable Construction

IN 2021 WE REDUCED OUR CARBON EMISSIONS BY 19%

2020/21 Revenue [GBP] 0.62 kg CO2

2021/22 Revenue [GBP] 0.50 kg CO2

There is a strong consensus within the scientific community that rising world temperatures are caused by human activity, and that construction plays a big part.

Globally, the construction sector accounted for more than 34% of energy demand and around 37% of energy and process-related CO2 emissions in 2021, as reported in the 2022 Global Status Report for Buildings and Construction.

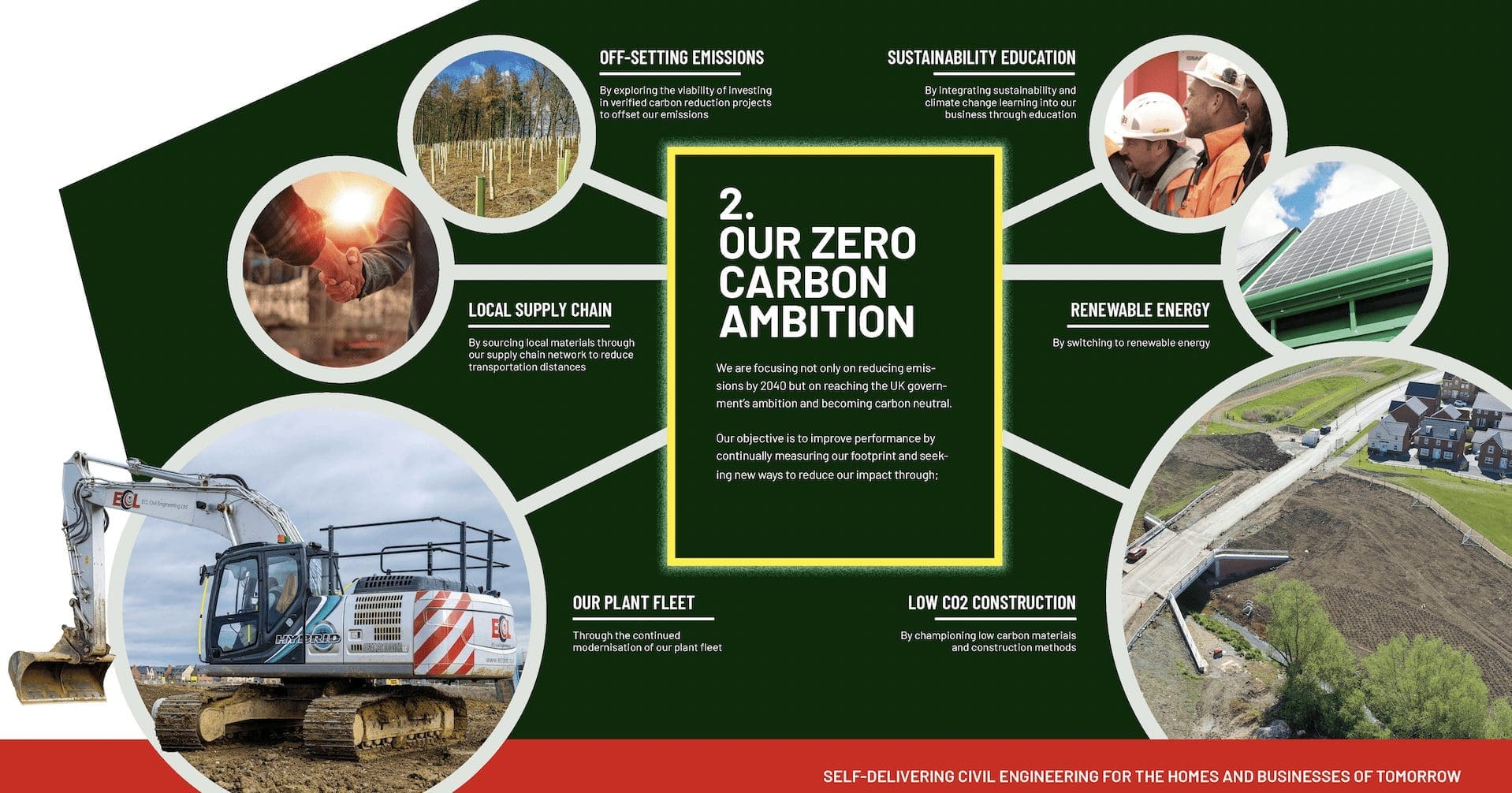

For this reason and as a conscientious business, we’ve been working hard to reduce our emissions and to bring awareness to our co-workers and supply chain about our environmental and carbon reduction plans.

Whilst we had already taken early action to reduce our emissions as early as 2017, it was only in July 2020, when we appointed a third-party company ‘ClimatePartner’ to externally calculate our baseline carbon footprint, that we were able to fully understand our corporate CO2 outputs and how to action an effective reduction plan.

Quantifying the company’s baseline carbon footprint was no light project to undertake. Still, our newly appointed ECO team ascended to the challenge and, over a six-month period, meticulously recorded emission usage for every facet of the business.

The resulting baseline report became the root of our carbon strategy and the starting point where we could methodically fulfil our carbon ambition by identifying our carbon hotspots to achieve the greatest potential for avoidance and reduction measures.

Two years on, and the ECO team has successfully driven change throughout the business, managing our ECO strategy with the same commitment as we run our projects. They have pursued value-added solutions and innovations to optimise emission reduction and meet our carbon reduction milestones well ahead of schedule.

In July 2022, our annual CCF Report (Corporate Carbon Footprint Report) showed an outstanding reduction of 19% of our overall carbon emissions. This is evidence of the excellent work and progress the company has made by taking significant environmental measures to reduce our footprint.

The extensive optimisation of our plant and vehicle fleet and our low-carbon construction approach have played a major part in the drop in last year’s emissions.

And with multiple micro-actions in progress, such as renewable energy trials and supplier communications, we anticipate these endeavours to not only create carbon savings but will set new standards for greener construction methods and procurement.

Site renewable energy

In early 2022, hybrid power generation systems (Solar pods’) were installed in 2% of our projects. The team are now evaluating the Solar Pods’ seasonal carbon savings to review if roll-out across all sites is a workable solution.

Plant fleet

Upgrading 50% of our plant fleet last year with ultra-low emissions diesel engine technology and the remaining 80% with the Fuel Active system has resulted in a staggering 6% reduction in plant fuel emissions.

“Regarding plant machinery, we have extensively researched manufacturers to find those producing the most fuel-efficient machinery and emission-friendly engines.

For now, the hybrid option in machinery and vehicles serves us best as a business until we have the infrastructure to fully support an all-electric fleet.” added Steve Wright, ECL’s Plant Manager.

Vehicle fleet

With our vehicle fleet, our ambition to replenish vehicles fell short as the Covid pandemic and the consequent supply chain issues made fleet acquisition extremely challenging; however, despite this disruption, we have successfully updated 5% of our vehicle fleet with the Toyota Corolla Hybrid Van models, and we’re back on track, ready to replenish older company vehicles with EV and hybrid models or other ultra-low emission solutions where EVs are not viable.

With the use of EV models set to rise within the company, Sean Hoare, Managing Director and Barry Wright, HSEQT Director, have been exploring a viable solution to incorporate EV charging points onsite.

Barry, added;

“We are keen to roll out a programme to have accessibility to electrical charging points on site with or without connections to the grid.With new technologies such as ‘EV ARC’, the first stand-alone charging station powered by solar, and ‘EV Street Charge’ providing pay-as-you-go public-facing EV charging points connected to street lights and other emerging technologies, accessibility is looking promising.

Having EV points would not only benefit our projects by producing less greenhouse gas emissions but, just as importantly, they’ll create a significantly quieter and, therefore, safer environment.”

Low CO2 construction approach

Early last year, the ECO team introduced a new procedure within the Infrastructure Department to offer a second quote at tender and provide clients with a carbon-saving alternative incorporating HVO fuel and vehicle movement savings and low-carbon and recycled product alternatives.

Phil Eastment, newly appointed Head of Delivery within the Infrastructure Department, commented:

“This is a new initiative for ECL, and it is absolutely the right approach. We have clients who have a mutual drive to minimise their carbon impact and proactively request low-carbon construction methods.We fully understand that the low-carbon construction approach will only be feasible for some projects at this moment in time. However, by effectively demonstrating cost and emission savings through greener construction methods, we are confident that more and more of our clients will gradually adopt a greener and cleaner construction approach.”

The company is currently assessing the viability of Hydrotreated Vegetable Oil (HVO) instead of diesel for use on significant infrastructure projects. Using this fuel could reduce plant vehicle emissions by 90%.

Hydrotreated Vegetable Oil (HVO) is a new generation of bio-based diesel that is much cleaner-burning and far less prone to problems than the first-generation FAME (Fatty Acid Methyl Ester) biodiesel.

This new generation of renewable diesel is a clear, colourless, odourless liquid chemically identical to fossil-based diesel but with less carbon dioxide emissions. The unit cost of HVO is significantly higher than regular diesel; nevertheless, this could be the quickest and simplest route to a cleaner, greener construction future.

A client eager to champion sustainable development adopted our soil recycling programme for Clipstone Park. The innovative programme reduced costs associated with abandoned excess soil or acquiring refill soil from an offsite location.

The plant team are currently calculating Clipstone Park’s cost and CO2 savings to help promote this initiative to further clients.

2023 focusing on sustainable procurement

We recognise that our purchasing decisions and activities have an environmental impact. This year our focus is to ensure these impacts are minimised and, where possible, are positive. We are therefore committed to embedding sound sustainable principles within our business to ensure that we procure sustainable, ethical and responsibly sourced goods and services that not only represent value for money but also have a positive value to society, the economy, and the environment.

Steve Tysoe, Managing Director, commented;

“We have clearly set ambitious carbon reduction goals, with the intention to be carbon neutral by 2035. By doing this well, we are supporting the responsible growth of our business.Each year, we review our performance and publish the results in our annual Corporate Carbon Footprint Report. This is us being completely transparent and accountable.

This year’s report shows how we have lived true to our commitment, with an outstanding carbon reduction for the business overall of 19% in 2022. To continue with this momentum, we need to focus on working with our partners and supply chain to constantly stretch ourselves and meet next year’s ambitious targets.”