ECL lay the first recycled asphalt at Newark

GROUNDBREAKING MOMENT FOR NOTTINGHAMSHIRE

Nottinghamshire has become the new face of sustainable construction. At the Urban&Civic Middlebeck development, ECL has raised the bar for worldwide environmental stewardship through groundbreaking carbon-friendly strategies.

Construction is one of the UK’s largest polluters, responsible for around 25% of greenhouse gas emissions. The industry is in urgent need of change, and ECL is at the forefront. This year, the company’s objective was clear: to fulfil the demand for a greener approach to construction and establish a valuable example for the transition into a more sustainable future.

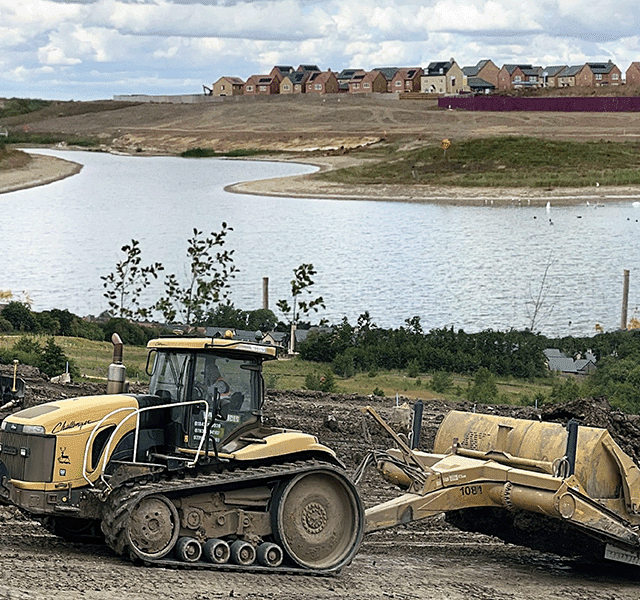

Beginning August 2023, the company was contracted by Urban&Civic to manage the first phase of infrastructure for Staple Lane, Middlebeck, a 694-acre urban extension just south of Newark and Nottinghamshire’s most significant development to date.

Sustainability was a priority from the outset, and since the project began, the team has initiated huge strides towards low-carbon construction to achieve a carbon saving of equal proportion.

Since August 2023, the installation of solar-powered generators on the Newark compound has saved 13,000 litres of diesel, equivalent to 42,000kg of CO2. Even the company’s diesel-powered machines set an admirable example. Over 400 machines are equipped with the Fuel Active System that takes diesel from the top of the tank to reduce the strain that water and dirt place on the engine. This modification alone saves 1-2 litres of fuel an hour.

In preparation for the reconstruction of Staple Lane and the Southern Link road connecting the A1 access section (East) between the A1 and A46, ECL’s site team, headed by Project Manager Dan Bartram, reclaimed 45,000 m3 of subsoil to create new gradients and inclines and raise the new road design above flood levels. The machinery used throughout this stage was powered entirely by HVO fuel: diesel’s renewable, fossil-free adversary and a single change that cut fuel emissions by 299t CO2e- a staggering 90% reduction!

The company’s consistent search for new sustainable construction methods and materials has ensured its carbon savings don’t end there. Foamix, a proven recycled tarmac, was a joint initiative from Urban&Civic and ECL, brainstormed during programme delivery, is undoubtedly the star of the show.

With approval from Nottinghamshire County Council to introduce this revolutionary recycled asphalt to Nottinghamshire’s infrastructure for the very first time, 3,969 tonnes of the old bituminous surface at Staple Lane was milled and locally stored in readiness to be recycled, preventing yet more construction material from unnecessary decomposition in a landfill site.

Commencing on the 29th of April 2024, a rotation of trucks transported 3,493 tonnes of Foamix over multiple days, each tonne effectively reducing CO2 emissions by 27kg!

Keiran Devane, ECL’s Visiting Manager for the Newark project, commented,

“The successful use of Foamix on the A14, a project of significant scale, is a testament to its quality and effectiveness. I’m confident that the industry will not only embrace but also champion this approach on a global scale. I am pleased that ECL is paving the way in this innovative shift, a fact that the whole team can take pride in.”

A highways manager from Nottinghamshire County Council added,

“We welcome working with partners on projects such as this, particularly with such innovative solutions. We are committed to helping to reduce the county’s impact on the environment, working towards making all council activity net carbon neutral by 2030.”

Incredibly, Foamix’s benefits do not end there. The proven foamed bitumen and cold paving technology requires much less energy to produce than hot mix asphalt and promises an enormous 45% carbon savings. Yet, of equal importance, Foamix can be laid down cold; this not only enhances safety but also speeds up installation. The result is an efficient alternative to traditional tarmac that guarantees practical benefits alongside essential carbon savings.

Mike van den Berg, Development Director for Urban&Civic at Middlebeck, stated,

“Urban&Civic are deeply committed to delivering the UK’s residential housing needs in a safe, sustainable and responsible way that creates long-term value. Sustainability remains fundamental to the quality of what we deliver and how we work with our partners, the communities around us and our people. We’re always looking to find new ways to reduce carbon emissions on our developments and we’re delighted to see ECL leading the way with environmental initiatives at our Middlebeck development.”

The Newark project proves that by using low-carbon fuels, technology, and closed-loop construction, the industry can transform old roads into new ones, provide environmentally sustainable infrastructure, and deliver quality results for the client.

Now imagine an equal saving across thousands of construction companies worldwide.