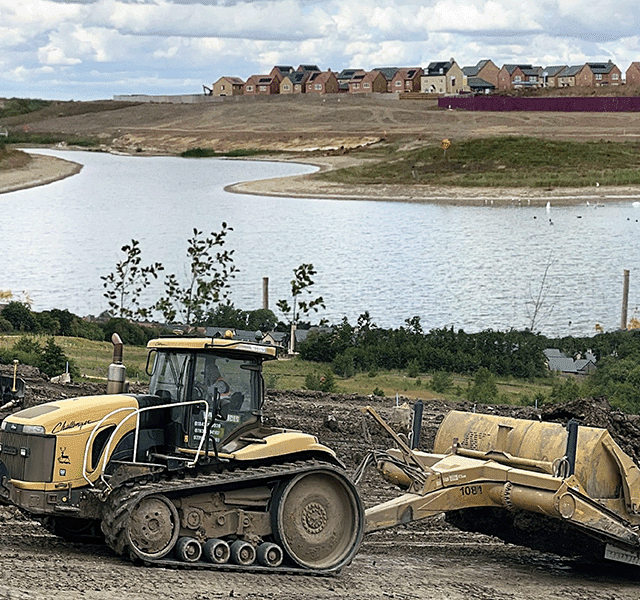

Groundworks are essential to the development of new buildings and communities as it is commonly the first step in the construction process.

TABLE OF CONTENTS

- Groundworks meaning

- What do Groundworks Involve?

- Different Types of Groundworks Activities

- 7 qualities of a top groundworks company

- We also recommend

Groundworks meaning

The meaning of ‘groundworks‘ refers to the work carried out to prepare the ground and below ground to enable the start of a construction project. In short, Groundworks is the first set of activities involved on a construction site that lead to the foundations being laid.

What do groundworks involve?

Groundworks involve a whole range of services, and the services needed will vary for each construction project. Aside from any demolition works or site enabling works that may need to be carried out, groundworks fundamentally involve; ground investigation, site clearance, installation of footings and foundations and the provisions for drainage, cabling and the installation of utilities such as fibre optic cables, telephone lines, and gas pipes and finally landscaping.

Different types of Groundwork Activities

- Ground investigations

- Site clearance

- Trenching

- Retaining walls

- Sheet piles

- Sewer Construction

- Basement Construction

- Temporary and permanent drainage

- Specialist tunnelling

- Landscaping

- Surfacing roads and car parks

- Foundations

Ground investigations

A ground investigation is an extensive investigation of a potential construction site to determine any possible issues, the condition of the land and any past uses of the site which could cause problems during building. Our highly qualified team conducts these investigations to ensure that all safety precautions are considered before construction starts.

Site clearance

Site clearance is the process of removing any debris before construction begins. This can include any former constructions, soil, plant roots or any hazardous material to ensure the site’s safety. The machinery commonly used to carry out a site clearance would be 360 excavators with a tilt rotator attachment such as hydraulic selector grabs and breakers. For large scale projects, we would use our CAT 963 or 953 loading shovels or one of our D6 or D3 Komatsu dozers. These extensive machines make the job a lot quicker and safer to manage.

Trenching

Trenches are shallow holes in the ground created for laying pipes and telephone wire or for manufacturing foundations. For large groundwork projects, we use 14T JCB140W Duck which is a wheel excavator ideal for tracking on firm surfaces. In addition, these excavators are also GPS enabled, meaning the machine can perform an excavation automatically.

The GPS excavators receive their positioning data from a digital 3D map created in-house. The operator simply plugs in a USB stick containing the pre-programmed 3D digital map into the excavator’s monitor and then activates the excavator, which works in full automation mode allowing the GPS positioning data to guide the bucket to the exact contours of the design grade. This high-tech machinery enables us to manage trenching with exact precision. In addition, they prevent over digging, improve safety and increase productivity.

Retaining walls

Retaining walls are rigid vertical walls constructed to support soil, water or other materials laterally. They are constructed to hold back materials and prevent them from slipping down a slope.

We more commonly construct retaining walls to hold back soil. This prevents erosion in an area should the soil slope downwards.

Sheet piles

Sheet piles are used to produce walls to allow for excavations to take place or for the retention of soil. Piling rigs or hydraulic excavator attachments machinery is used to force the sheet piles into the ground to ensure that the sheet piles are installed correctly and safely.

Sewer construction

Sewer construction is when a channel or pipe is created to remove waste and water from a site. To channel the sewer, we generally use a 360 excavator. The excavators will range from 5 Tonne to 50 Tonne in size, with the project determining which size machine is needed. In addition, we’d also use several attachments, each needed to perform a particular job at hand.

When hazardous materials are present during sewer construction, attachments to the excavators are utilised during its disposal, securing that our onsite workers and machine operatives remain safe and never in close contact with possible harmful materials.

Basement construction

Basement construction is the production of a building or part of a building below ground level. This can be done to provide extra space on the same plot of land or provide a secure footing for the structure of a building.

Temporary or permanent drainage

Temporary and permanent drainage systems are created to remove groundwater from a construction site and prevent the site from becoming waterlogged. Typically, an open-ditch drainage system or a pumping system is used to remove the groundwater. These systems make conditions onsite safe for our team to work and help prevent any delays to our project programme.

Specialist tunnelling

Specialised tunnelling is where below-ground tunnels are manufactured for appliances such as waterworks or rail lines. Specialist direction drills and boring equipment are used to create the underground tunnels and ensure they are secure and safe to hold any necessary equipment.

Landscaping

Landscaping is the altering of the pre-existing landscape. This can be changes to the terrain, such as the trees and ground type, or the removal of older constructions from the site. Our landscape team is often called in to expertly change the land’s topography, giving a finished look at the end of a construction project.

Surfacing roads and car parks

The surfacing of roads and car parks is done to ensure they have a long lifespan and are durable. Modern road surfaces need to have the ability to endure an incredible amount of wear and tear. In addition, They need to withstand the ever-rising influx of traffic and size of vehicles from large MPV’s (family-sized multiple people vehicles) to colossal construction and freight vehicles.

The technology behind road surfacing has undoubtedly come a long way with different materials and laying techniques employed when surfacing a road depending on its design and usage.

3 materials used for surfacing roads and car parks

- Concrete

- Asphalt

- Aggregate

Concrete

Typically concrete is used within areas with a low traffic level, such as local roads, sidewalks and other paths utilised by pedestrians. Concrete is a traditional road surface and has been used as far back as Roman times.

Asphalt

Asphalt was first introduced in the 1920s. It offers superior levels of flexibility in terms of installation alongside excellent water resistance.

Asphalt is commonly used on major motorways and smaller roads because it’s considered a robust, economical material that gives a clean and uniform finish and is easy to repair.

The plant machinery we commonly use to surface an asphalt road would be Asphalt pavers and Roller machines to level and finish the surface.

Aggregate

There are times when we will use a combination of asphalt and concrete to surface a road. This is particularly common when repairing a damaged road, as aggregate can be placed directly on top of an existing surface.

Foundations

Foundations are used to ensure the weight of a construction is distributed evenly and to create a steady base for a construction to be placed.

The machinery we generally use to manage the work needed to stabilise the ground and create the foundation support are 13Tonne or 14Tonne 360 excavators. These machines are enabled with GPS, which run Trimble or Topcon machine control. These additional control components provide a technology designed to automate depth control when digging to grade in flat, stepped or sloped applications. The technology also means that our operators only move the earth that is required, which in turn avoids over-digging – saving additional costs of fuel and unnecessary transportation of materials.

Furthermore, using the most advanced GPS technology and sensors, we allow our experienced operators to work better and faster whilst providing additional safety to our workers. Operators receive real-time on-screen bucket location and design views which means they can cut more accurately and check against complex designs in the cab, removing the need for someone to check the grade from the trench.

7 qualities of a top groundworks company

- Full Self-Delivery Model

- Exceptional Health & Safety Record

- Scope of Projects and Expertise

- Existing Client Partnerships

- Experienced Team

- Company Culture

- Project Programming and Delivery Models

Specialist Groundworks Provider

ECL Civil Engineering is on the rise, we have a strong company culture where families work alongside each other, and careers can be fast-tracked if you have the right work ethic.

We encourage everyone to feel part of the team. It’s hard work, but it’s well rewarded through social activities, recognition and remuneration.

Furthermore, ECL is fast becoming one of the top groundworks and civil engineering companies in our region with awards from the Sunday Times Top Track 250 and 1000 Companies to Inspire Britain.

Above all, we’ve earned a well-deserved reputation for quality and on-schedule delivery for a wide range of groundworks and civil engineering projects. The company is growing year on year, and we are one step forward to reaching our vision.

Our Vision

TO BE THE UK’S LEADING NAME IN CIVIL ENGINEERING, SETTING LANDMARK HEALTH AND SAFETY RECORDS AND PARTNERING WITH PIONEERS IN TECHNOLOGY TO OFFER WHAT NO OTHERS CAN.

SUNDAY TIMES TOP TRACK 250 AWARDS – 2019 & 2020

For another year running, ECL has been revealed as one of the UK’s leading mid-market businesses in the Sunday Times Top Track 250 awards.

1000 COMPANIES TO INSPIRE BRITAIN AWARD – 2017 / 2019 & 2020

ECL received the 1000 Companies to Inspirer Britain award for the third consecutive year. This award celebrates some of the fasting-growing and most dynamic SMEs in the UK, and we’re pleased to be acknowledged for our successes and innovation within our industry sector.

As one of the biggest civil engineering companies within the Bedfordshire region, we are currently invested in several large scale civil engineering and groundworks projects.

With our self-delivery model and the latest technology, we have raised productivity and are delivering groundworks and infrastructure schemes quicker than ever before.

To see how ECL Civil Engineering can help with your Groundwork or Civil Engineering Project, please get in touch.