and how to prevent accidents and deaths in construction

This article’s been written to address the top Safety Hazards in Construction and advise how best to prevent accidents and deaths in construction from happening.

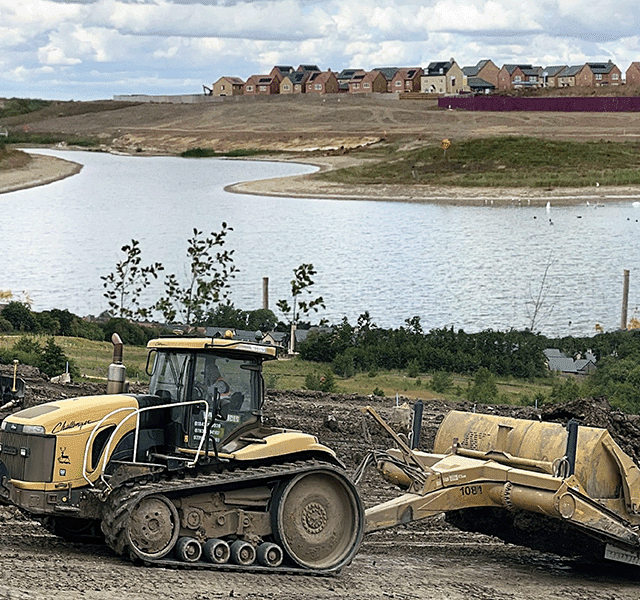

A construction site is an area of land where roads, buildings, or some form of infrastructure are being built or renovated.

Working on a construction site will mean you will be working with or alongside large operational plant machinery and tools, working at height and in environments where hazardous materials may be present.

Because of the nature of the work, construction is one of the most dangerous industries in the UK, with 40 workers suffering fatal injuries in 2020.

The dangers in construction are heavily dependent on the type of construction work that is being carried out. For example, working with asbestos presents entirely different hazards to working at heights. This article outlines common construction hazards found within civil engineering and how to work safely to prevent them.

Construction Hazards

Here’s a list of construction hazards and guidelines to prevent accidents or deaths in the industry:-

Working at Heights

Working from heights is the most common cause of fatal injuries to workers. The HSE estimated that 47% of worker fatalities were due to a fall from height. All employees who work at height need suitable training in working on different pieces of equipment, and such work must be planned appropriately. Safety approaches and precautions should be adopted, such as:

- Where practical, avoid the need to work at height.

- Put collective measures in place where working at height can’t be avoided to prevent falls. Such as the use of equipment to provide an extra level of safety to reduce the risk of a fall—for example, a scaffold with a double guard-rail or edge protection.

- Minimise the consequences of a fall by providing a safety net.

- Wear the necessary P.P.E. such as a safety harness.

Moving Objects

The HSE report that 12% of incidents on site are due to being struck by a moving vehicle or object. A construction site is an ever-changing environment, with many objects moving around, often on uneven terrain. Delivery vehicles, heavy plant machinery and overhead lifting equipment pose a hazard to site workers and operators. Sites should always be planned to manage plant and pedestrian interface where physical barriers and suitable segregation is in place.

To reduce risks, workers should:

- Never stand behind large operating plant machinery and never stand under suspended loads.

- Avoid working close to moving object and be careful of their surroundings, especially if they do not have lights or beepers.

- Always ensure you have a banksman to guide plant vehicles when reversing or manoeuvring on a public road.

- Always wear PPE (Personal Protective Equipment) such as a hard hat and high visibility jacket to ensure you are seen.

Slips, Trips, and Falls

Slips, trips, and falls can happen in almost any environment, and, in construction, there are slightly fewer incidents of these kinds of injuries than in other industries. The HSE reports that around a quarter of injuries reported are due to Slips, Trips and Falls. As construction sites often have uneven terrain and the typography is forever changing, it is unsurprising that slips, trips, and falls are a common hazard.

HSE reports that several thousand construction workers are injured every year following a slip or trip. Most of these could be avoided by effectively managing working areas and access routes, such as excavations and footpaths.

Managers and Black hats (site supervisor) on construction sites must effectively manage the site so that workers can move around it safely. Risks should always be reported and sorted to reduce the chances of injury. To reduce harm due to Slips, Trips and Falls, you should:

- Ensure that all operatives are provided with obstruction-free access and egress to their working areas.

- Keep work and storage areas tidy and designate specific areas for waste collection.

- Where surfaces are slippery with mud, they should be treated with stone.

- Where surfaces are slippery with ice, they should be treated with grit.

- All slippery areas should be signposted, and footwear with a good grip should be worn.

Noise

Working around loud, excessive and repetitive noise can cause long term hearing problems, such as deafness. Noise can also be a dangerous distraction and may distract the worker from the task at hand, which can cause accidents.

A comprehensive noise risk assessment should be carried out where the risk assessment has highlighted a noise hazard with the works to be undertaken.

Hand Arm Vibration Syndrome

HAVS (Hand Arm Vibration Syndrome) is a debilitating and painful disease of the blood vessels, nerves, and joints. It is typically caused by the continued use of hand-held power tools, including vibratory power tools and ground working equipment.

There are nearly 2 million people at risk of developing HAVS, resulting in the inability to do fine work, and cold temperatures can trigger painful attacks on the fingers. Once the damage is done, it is permanent.

HAVS is preventable if construction works are correctly planned to minimise exposure to vibration during work and workers are monitored are given appropriate protection when using vibrating tools and equipment.

Material Handling – Manual and by Equipment

Materials and equipment are constantly being lifted and moved around construction sites, whether manually or by equipment. Either way, handling carries a degree of risk.

For manual handling, training must be provided to ensure employees can lift and carry materials safely.

For lifting equipment handling, there are lots of risks, especially when operating lifting equipment on uneven ground. If an employee is required to use lifting equipment, they must be trained to operate the equipment safely, and a regular test should be taken to check their ability to use the equipment. Always check your plant is fit for use and that it’s certificated and inspected before use.

Excavations

Incidents commonly occur within excavations on construction sites, such as an unsupported excavation collapsing with workers inside.

Here are some safety measures that need to be put in place to prevent excavations from collapse and to reduce the risk of operatives falling into excavations.

- Never work in an unsupported excavation.

- Ensure an excavation is supported and fully secure.

- Regularly inspect the excavation both before and during the work shift.

- Always check that the edge protection of an excavation is 100% intact before you enter it.

- Always maintain a safe distance from the edge of all deep excavations.

Asbestos

An estimated 500,000 public buildings in the UK are thought to contain asbestos. Asbestos kills around 5,000 workers per year, and an average of 20 tradespeople die every week due to past exposure.

Asbestos is a naturally occurring fibre that was used up until the late 1990s in the UK.

There are three types of asbestos fibres commonly used in the UK, these are, blue (crocidolite), brown (amosite) and white (chrysotile).

When asbestos is damaged, it realises these fibres into the air, and once inhaled, these fibres can cause severe and fatal diseases such as lung cancer, asbestosis, and pleural thickening.

Workers on construction sites must be trained to understand what to do should they come across any suspicious materials that may contain asbestos.

If there is asbestos on the construction site, workers must be informed where it is and how to handle it safely. When handling asbestos, you need to wear fully regulated PPE equipment at all times to prevent fibres from being inhaled or absorbed through the skin.

Electricity

HSE reports that 1,000 electrical accidents at work occur every year. Most of these accidents arise from contact with overhead or underground power cables and electrical equipment/machinery.

In civil engineering, strikes to services are common. The strikes happen when excavation is undertaken without adequately checking the ground for existing services. Consequently, incidents can easily be avoided by using technology such as CAT and Genny scanning equipment to scan an area and foresee potential services and prevent service strikes.

Airborne Fibres and Materials

Unsurprisingly, a lot of dust is produced on construction sites. This dust is often an invisible, fine, and toxic mixture of hazardous materials and fibres. This can damage the lungs and lead to chronic obstructive pulmonary disease, asthma, silicosis and other such diseases. All employers have to ensure protective equipment is used.

Site Security

Having inadequate security around a construction site may danger the public and lead to an unnecessary incident. Always make sure that boundary safety fencing is 100% secure and there are no openings for the public to access.

The top eleven safety hazards in construction are:

Working at height

Moving objects

Slips, trips, and falls

Noise

Hand-arm vibration syndrome

Material handling – manual and by equipment

Excavations

Asbestos

Electricity

Airborne fibres and materials.

Site security